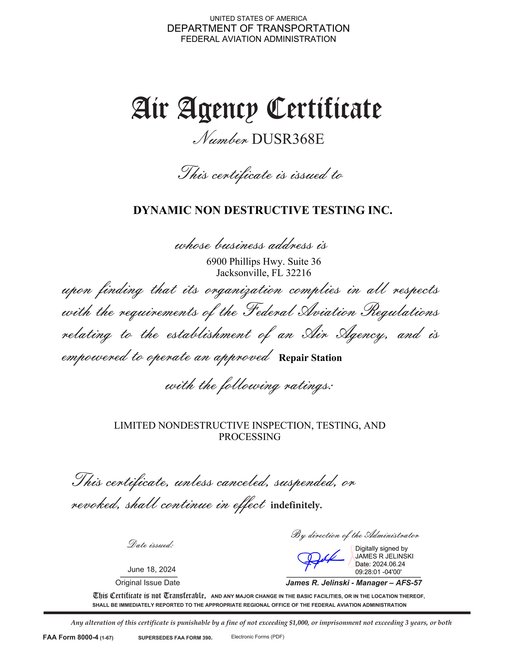

As an FAA Certified Repair Station, we are authorized to maintain and approve aircraft for return to service after repairs, following strict regulations outlined in FAA Part 145.

We are certified to perform the following NDT inspections on aircraft and aircraft parts:

- Fluorescent penetrant Inspection, IA W ASTM E1417

- Fluorescent Magnetic Particle Inspection, IA W ASTM E1444-El444M -11 / ASTM E709

- Eddy Current Inspection, IA W ASTM E 1004-02

- Ultrasonic Inspection, IA W ASTM E 190 I -08

- Radiographic Inspection, IA W ASTM E 1742-11

Air Agency Certificate can be downloaded here. If you would like to see our full opsec, you can download it here