The Variety Of Industries We Work With

Dynamic Non-Destructive Testing Inc. is a leader in the non-destructive testing and inspection field. Below are the different industries that we can work with. To schedule an inspection with us call at 904-375-9074.

AEROSPACE

Military aircraft, missiles, space, commercial airliners, and general aviation for the five markets within aerospace make it one of the largest and most powerful industries in the United States. The aerospace sector employs nearly 1,200,000 workers between scientific and technical jobs and the jobs in the related fields. Engineers, scientists and technicians are where 25% of these employees work due to the importance of research and development. At a rate of 14% a year, aviation is one of the fastest growing industries in the United States.

Due to the millions of individual parts required for flight vehicles, the aerospace industry’s product line is very broad. In order to operate and maintain the vehicles, there are many support systems needed. The U.S. Department of Commerce did a study and the direct and indirect exports from aerospace support more jobs than the export of any other goods. $143 billion in export sales from the U.S. aerospace industry went to the U.S economy.

NASA was successful with their National Advisory Committee for Aeronautics and the Mercury manned space program was initiated in 1958. To promote American civil aviation, the U.S. Aircraft Industries Association was formed in 1919. In 1959, the name was changed to the Aerospace Industries Association. The AIA is an aerospace industry-funded organization and is where technical and policy issues can be handled. Some of America’s largest aerospace companies that make up the membership of the AIA are Boeing, Lockheed Martin, L3Harris Technologies, United Technologies, Honeywell, Raytheon, SpaceX, Blue Origin and Textron.

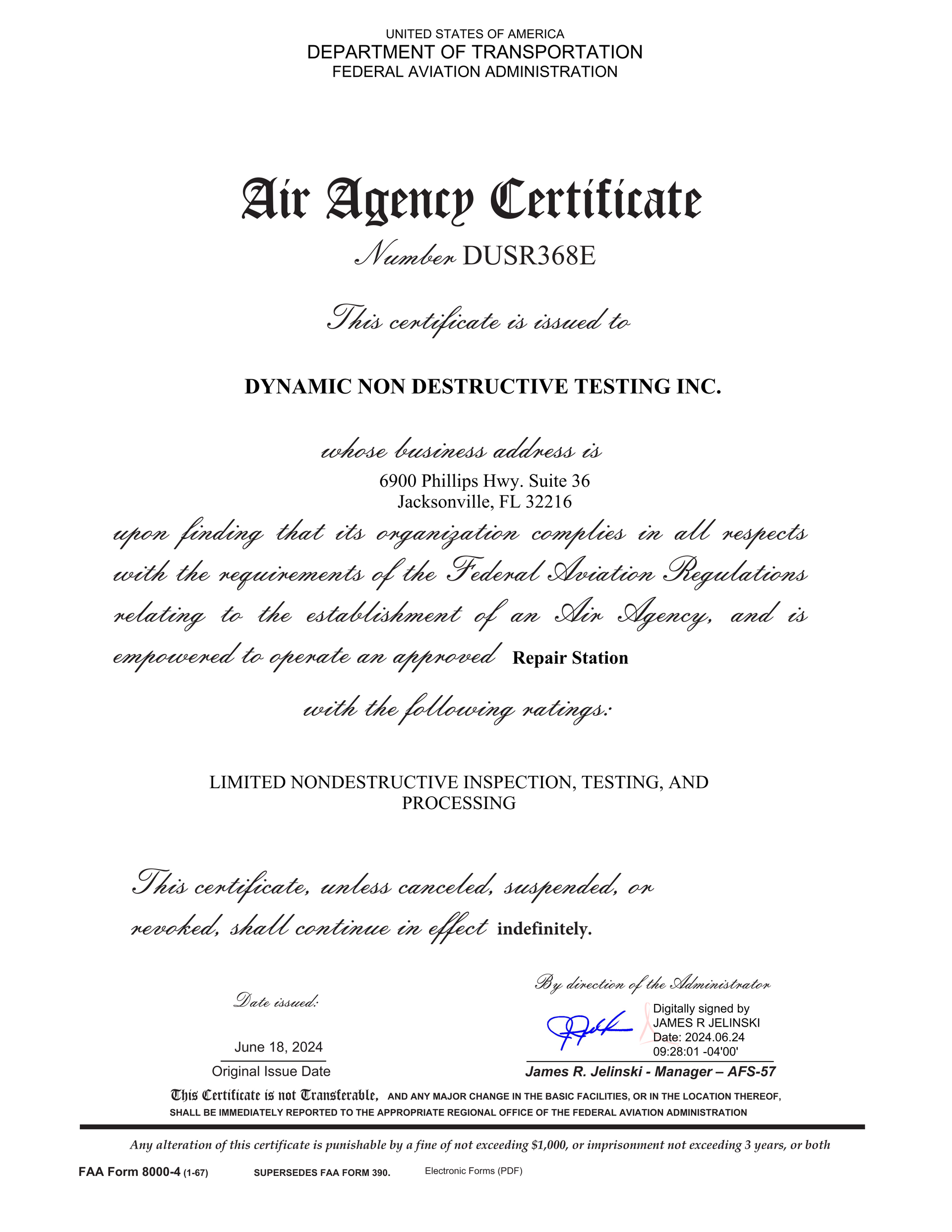

As an FAA Certified Repair Station, we are authorized to maintain and approve aircraft for return to service after repairs, following strict regulations outlined in FAA Part 145.

We are certified to perform the following NDT inspections on aircraft and aircraft parts:

- Fluorescent penetrant Inspection, IA W ASTM E1417

- Fluorescent Magnetic Particle Inspection, IA W ASTM E1444-El444M -11 / ASTM E709

- Eddy Current Inspection, IA W ASTM E 1004-02

- Ultrasonic Inspection, IA W ASTM E 190 I -08

- Radiographic Inspection, IA W ASTM E 1742-11

Air Agency Certificate can be downloaded here. If you would like to see our full opsec, you can download it here

POWER

Example Of A Power Station

The power plant generator is a device that converts mechanical energy obtained from an external source into electrical energy as the output. It is important to understand that a generator does not actually ‘create’ electrical energy. It uses the mechanical energy supplied to it to force the movement of electric charges present in the wire of its windings through an external electric circuit.

Power Generation Industry

The power generation industry can be split into three areas: power generation, transmission and distribution networks, and metering and sales. Large energy companies tend to operate in all three areas, as it is more cost effective, but smaller companies often only work in one of these areas.

In each plant, whether fossil-fueled or nuclear, the following basic power generation equipment is present:

Heat Source

Provides heat to generate steam. In a nuclear power plant, the heat source is the nuclear reactor, often referred to as the reactor core.

Turbine & Generator

Uses the energy of the steam to turn a turbine/generator that produces electricity.

Condenser

Condenses the steam back to water so that it can be returned to the heat source to be heated again.

Pump

Provides the force to circulate the water through the system.

TURBINES

Electrical power starts at the power plant. In most cases, a power plant consists of an electric generator. Something has to spin that generator — it might be a water wheel in a hydroelectric dam, a large diesel engine or a gas turbine. But in most cases, the object spinning the generator is a steam turbine. The steam might be created by burning coal, oil or natural gas. Or the steam may come from a nuclear reactor.

STRUCTURAL STEEL & INFRASTRUCTURE

The United States structural steel industry supplied fabricated and erected structural steel framing for over 10,000 buildings, bridges and industrial facilities through a network of producers, service centers, steel fabricators and erectors. Steel plate is used in the construction of both bridges and buildings and is produced domestically in both electric arc and basic oxygen furnaces. The weighted average based on production method for recycled content of plate used in construction applications is 75%. U.S. plate producers serving the construction market. Sustainability Structural steel has long been considered the premier green construction material, and the structural steel industry continues to improve its leading environmentally friendly position by further reducing greenhouse gas emissions.

- The dominant market share of structural steel demonstrates the continuing recognition of the advantages structural steel brings to building projects. Architects, structural engineers, general contractors, transportation departments and building owners choose structural steel because:

- Structural steel is fabricated off-site under controlled conditions, ensuring high-quality and reducing the number of costly fixes at the job site. This also allows for just-in-time delivery, which accelerates overall project schedules.

- Structural steel is reliable and predictable. It’s produced to precise tolerances and consistent strength levels. There are no secrets with steel—what you see is what you get. Steel is strong, lightweight, durable, impact resistant, straightforward to inspect and easy to refurbish or repair. This makes steel easier to design and use.

- Structural steel is at full strength as soon as it’s erected, which makes project schedules predictably shorter. For the same load and span requirements, a steel girder will require less depth than a corresponding concrete girder efficiently addressing any vertical clearance or complex geometry issues.

- Bridge and building life spans exceeding 100 years are common place. High performance weathering steel and coating technologies provide reliable protection from corrosion when steel is exposed to the elements.

- Structural steel leads the construction industry with a fully integrated supply chain that uses advanced technology at all stages of design and construction. This technology has been proven to reduce or eliminate errors, improve safety and lower project costs.

- Today’s modern mills produce structural steel containing over 95% recycled material. At the end of the life cycle of a building, 100% of the steel frame can be recycled (the current recovery rate for structural steel is 98%). Steel is the premier choice for environmentally conscious projects. A new bridge requiring 500 tons of steel would typically use the steel from 300 old cars, 250 dishwashers, stoves and refrigerators, 60 tons of industrial scrap and 50 tons of recycled curbside waste.

- Structural steel provides owners with buildings that generate revenue earlier, maximize the amount and use of floor space, are easy to modify and easier to sell, and are aesthetically pleasing.

- Structural steel is the most economical building framing material for both buildings and bridges. Erection costs are lower because construction with steel is faster and lighter requiring smaller and fewer pieces of equipment for a shorter period. Foundation and pier costs are less because steel is lighter. Less steel is required because steel can take advantage of composite design techniques maximizing the structural contribution of both the steel structure and the concrete deck.

- Structural steel used in bridges and buildings is aesthetically pleasing.

REFINING, PETROCHEMICAL & CHEMICAL

Petrochemical Industry

The petrochemical industry, which produces chemicals using oil and natural gas as major raw materials, occupies an important position in consuming sectors. The organic chemicals produced in the largest volumes are methanol, ethylene, propylene, butadiene, benzene, toluene, and xylenes. Ethylene, propylene, and butadiene, along with butylenes, are collectively called olefins, which belong to a class of unsaturated aliphatic hydrocarbons. Oil and natural gas are composed primarily of hydrocarbons. Chemical and plastic materials provide the fundamental building blocks that enable the manufacturing of the vast majority of these goods. Most petrochemicals contain hydrogen or carbon or both. Petrochemicals can be converted into thousands of industrial and consumer products, including plastics, paints, rubber, fertilizers, detergents, dyes, textiles and solvents. the industry consists of 2 major divisions. the primary petrochemical industry produces basic chemicals, such as ethylene, from oil or gas. The secondary industries convert the basic petrochemicals into materials that may be directly used by other industries. Demand for chemicals and plastics is driven by global economic conditions, which are directly linked to demand for consumer goods.

Standard of living is dependent to a significant degree on domestic petrochemical production. The availability of economic petrochemicals allows the domestic production of numerous items that could be more costly if imported. Many compounds now considered petrochemicals were formerly made from wood and coal. The industry has grown to supply the increasing demand for synthetic consumer products.

MARITIME

Some of the work and service that the maritime market includes are shipbuilding, shipping line operations and management, shipyard services, maritime cargo services, marine repairs and freight forwarding services. They are primarily related to commercial or mercantile activities. Some of the businesses that the maritime market supports are logistics companies, shipyard companies, loading and unloading ships, that is longshoremen or stevedores, import-export companies, shipbuilding companies, vessel equipment, components OEMs, metallurgy companies, steel mills, commodity terminal companies, energy terminal and transportation companies such as pipeline hubs, as well as various service industries.

Over 4000 bulk tankers are in use for transportation for energy, liquified natural gas, oil chemicals and liquid products worldwide. All non-landlocked markets, which is a majority of the world, are connected by the maritime shipping and traffic. Major macroeconomic trends affect global and transnational trade and the vessels used are constructed and decommissioned as needed. Freighters, bulk carriers, container ships, tankers and other large vessels are some of the maritime fleet used for transportation and shipping.

PIPELINE

Unknown to most people there are numerous miles (190,000-mile liquid petroleum and 2.4 million-mile natural gas pipeline) of pipeline that deliver liquid petroleum and natural gases that are a very important part of the American economy. This large network of pipelines reliably, safely, efficiently, and economically transfer and deliver products like gasoline, diesel, jet fuel, home heating oil, and natural gas.

The oil or gas starts in underground reservoirs where it is produced by the upstream sector. During this process the downstream sector refine s, markets and distributes the products. The oil and natural gas are transported from the upstream sector to the downstream sector where it is distributed.

Oil and natural gas must be delivered from the production site to a refinery to be refined into a final product such as gasoline. Companies within this portion of the energy sector are called mid-stream providers.

ABOVE GROUND STORAGE TANKS

Aboveground storage tanks — storage containers or systems of storage containers offer great versatility for a wide range of applications, located above the earth’s surface. Often found in industrial settings, above ground storage tanks can be used to hold various materials, including petroleum or oil, waste matter, water, chemicals, and hazardous materials.

Aboveground storage tanks used for the storage of petroleum products is regulated primarily under 40 CFR 112. The regulation does not actually use the terms "aboveground storage tank." Instead the term "bulk storage container" is used and is defined as "any container used to store oil. These containers are used for purposes including, but not limited to, the storage of oil prior to use, while being used, or prior to further distribution in commerce. Oil-filled electrical, operating, or manufacturing equipment is not a bulk storage container."

One of the many standards that apply to aboveground storage tanks is API 653, "Tank Inspection, Repair, Alteration, and Reconstruction." It was developed and published by the American Petroleum Institute (API) and it provides guidelines for the inspection, repair, alteration, and reconstruction of steel aboveground storage tanks used in the petroleum and chemical industries.

MANUFACTURING

The industrial production of goods in large quantities by employing machinery and equipment to standardize the production process. The manufacturing sector employs nondestructive testing to ensure compliance with regulations, risk management, safety, and quality control. Our nondestructive testing techniques can provide real time data so manufacturers can make informed decisions as quickly as possible.

Non-destructive and destructive testing ensures your production line stays active and maintains quality controll. Dynamic NDT is committed to making your product the best it can be before it hits the market.

MINING

The extraction and processing of minerals and metals makes up a large portion of the United States economy. With over ten thousand mines across the US, regulation and worker safety are top priorities. Non-destructive testing of heavy machinery used in mines across the states can require inspection up to every six months. Regular magnetic particle and ultrasonic inspections can ease worry of disasters above and underground.